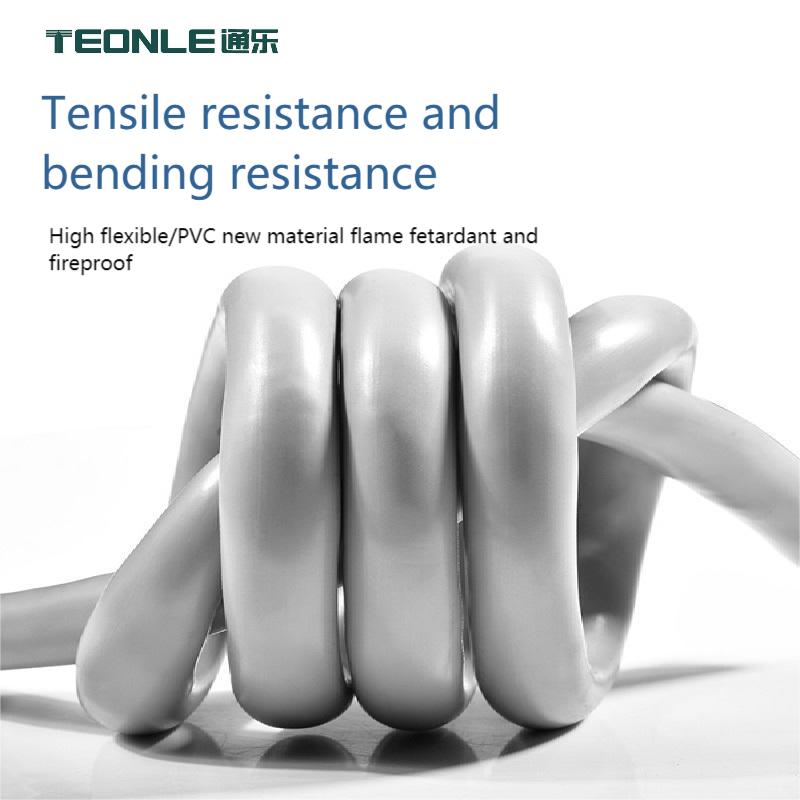

High flexible bending resistance TRVV cable product structure

Conductor: Multi-strand soft annealed oxygen free copper wire fine stranded according to VDE0295, class 6 conductor

Core wire: The core wire is twisted synthetic cable, the color of the core wire conforms to VDE 0293 non-woven material wrapped

Insulation: special high strength fatigue resistant composite nitrile PVC

Screen cover: tinned copper wire braid shield/fine oxygen free copper wire braid; The weaving density is greater than 85%

Outer sheath: imported nitrile mixed PVC/PUR

Jacket color: black and grey/can be customized according to customer's request

Product Introduction

Product model: TRVV

Number of cable cores: 1-80 cores

Cable square: 0.10-240mm2

High flexible bending resistance TRVV cable product structure

Conductor: Multi-strand soft annealed oxygen free copper wire fine stranded according to VDE0295, class 6 conductor

Core wire: The core wire is twisted synthetic cable, the color of the core wire conforms to VDE 0293 non-woven material wrapped

Insulation: special high strength fatigue resistant composite nitrile PVC

Screen cover: tinned copper wire braid shield/fine oxygen free copper wire braid; The weaving density is greater than 85%

Outer sheath: imported nitrile mixed PVC/PUR

Jacket color: black and grey/can be customized according to customer's request

Technical specifications of TRVV cable with high flexibility and bending resistance

Standard: Refer to DIN VDE 0250 standard

Minimum bending radius: 8.0×D for mobile installation (cable OD)

Mobile operating temperature: -15℃~70℃ (can be customized -40℃~120℃)

Operating voltage: ≤ 0.75mm2, 300/500V

≥ 1.0 mm2, 450/750V

≥ 10 mm2, 600/1000V

Test voltage: 1500V according to DINDE 0472 Part 509

≤ 0.75mm2, 2000V, 50Hz, 5Min

≥ 1.0mm2, 3000V, 50Hz, 5Min

Purpose

Scope of application

TRVV cable in the equipment unit needs to move back and forth occasions, in order to prevent cable entanglement, wear, pull off, hanging and scattered, often put the cable into the cable chain, the formation of protection of the cable, and the cable can also move back and forth with the drag chain, this can follow the drag chain to move back and forth and not easy to wear high flexible special cable called drag chain cable, Also commonly known as towed cable, tank chain cable.

Tow chain cables are mainly used in industrial electronics systems, automatic generation lines, storage equipment, robots, fire systems, cranes, CNC machine tools and metallurgical industries.

Characteristic

TRVV cable is a kind of oil resistant, wear resistant, cold resistant cable, good softness, aging resistance, long service life, suitable for oil pollution, low temperature environment is extremely harsh.

Performance

Technical specifications of TRVV cable with high flexibility and bending resistance

Standard: Refer to DIN VDE 0250 standard

Minimum bending radius: 8.0×D for mobile installation (cable OD)

Mobile operating temperature: -15℃~70℃ (can be customized -40℃~120℃)

Operating voltage: ≤ 0.75mm2, 300/500V

≥ 1.0 mm2, 450/750V

≥ 10 mm2, 600/1000V

Test voltage: 1500V according to DINDE 0472 Part 509

≤ 0.75mm2, 2000V, 50Hz, 5Min

≥ 1.0mm2, 3000V, 50Hz, 5Min